Working with High Voltage can be highly dangerous if we do not follow properly safety norms. Bad handling of high voltage can prove to be fatal and can cause tragedy. So preventing any tragedy from happening, we should follow some standards and install essential safety devices.

Maintaining safety norms not only saves the lives of Human Beings but also prevents our equipment from any damage. So here in this article, we will discuss multiple preventive measures.

☛ What You will Read here

When do we call Electric Vehicle a “High Voltage System”?

Generally, in an Electrical system, a voltage level up to 33,000 Volts is referred to as a high voltage system, but in the case of an electric vehicle, the figures are different. There are different types of Electric Vehicles available in the market, which can be distinguished as Two-Wheeler, Three-Wheeler, Four-Wheeler vehicles, and Heavy-duty Electric Vehicles.

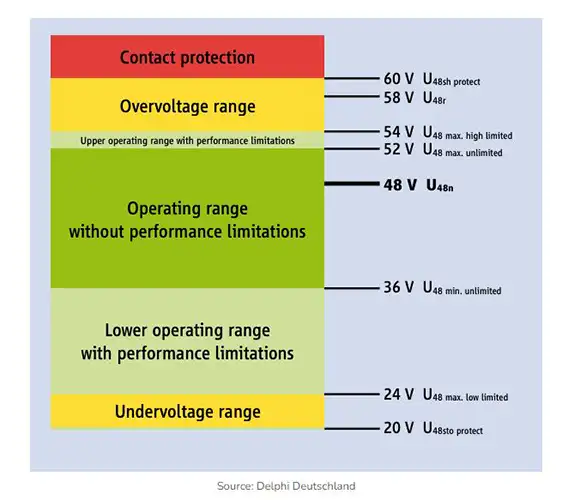

Different vehicles have different power ratings and different safety standards. Generally, voltages of more than 60 volts are referred to as high voltages in the automotive field. Two-wheeler and Three-wheeler electric vehicles operate on voltage ranges ranging from 24 V to 72 V according to their power requirements.

Must Read: Hop Korwin Electric Cafe Racer Spotted for the First Time

48 V voltage value is the most preferable value among Two-Wheeler and Three-wheeler electric vehicles manufacturers because it keeps the overall cost to a minimum value. Like Two-wheeler and Three-wheeler electric vehicles, Four-Wheeler vehicles have also a different voltage range on which they operate. Generally, the range for electric vehicles is 300 to 500 V, while the electric buses operate in the range of 800 V to 1200 V.

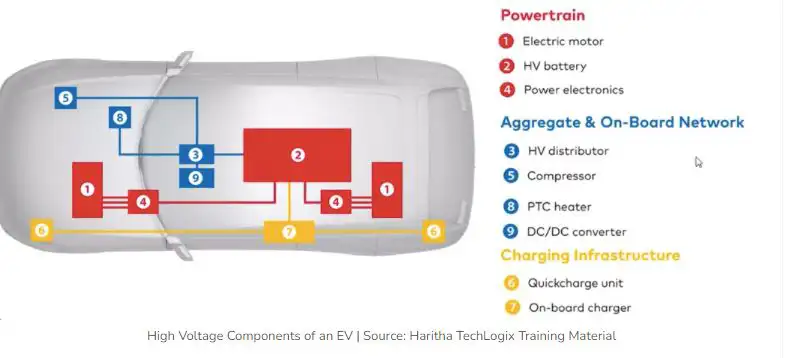

What are the different high voltage components in an Electric Vehicle?

All those components which are driven by the High Voltage battery pack can be labeled as High Voltage components. Some of that high voltage components can be listed as:

- The Battery Pack itself

- Electric Motor

- Inverter

- DC-DC Converter

- Compressor

- In-board charger

- Power Distributor

- Air Conditioner

What are the risks associated with High Voltage?

The only risk associated with High Voltage is getting shocked, which can lead to serious injuries, Burns, and death as well. Our body has a high resistance value of 10,000 Ohms (Dry) and 1000 Ohms (Wet) but still, the high voltage can be fatal to the Human body.

It’s a very common myth among people that voltage kills you, but the truth is that it’s the current that kills you. Voltage is the driving force that is responsible for circulating current in any closed circuit. The current of very low values even in milliamperes could be dangerous for a Human being if working with high voltage. Normally, the human body can feel shocked if subjected to an AC of 1mA and DC of 5 mA. Exceeding these values can increase the severity of discomfort felt by the human body.

Must Read: How to make a Career in Electric Vehicle Industry?

What safety standards do we need to follow to ensure the safety of employees?

There are multiple safety standards formulated by International and specific organizations of countries that ensure the safety of the employees. One such safety standard created by the US states named OSHA (Occupational Safety and Health Standards) 1910.132 ensures that the worker must wear protective equipment before getting engaged in work. PPE Kits, Rubber Boots, Gloves, etc. must be provided to the employees, and necessary safety training must be provided to the employees.

What safety equipment is necessary for ensuring a safe working environment for the workers?

- PPE (Personal Protective Equipment) kit must include the following equipment:

- Insulated Gloves

- Insulated Boots

- Goggles

- An insulated rod, to separate the person if he gets in contact with the High Voltage circuitry.

Apart from these, there should be necessary signboards such as High-Voltage signs and all those which are necessary.

Which job roles in the EV industry need to be aware of these safety standards?

All those workers which are working in the EV factory need to be aware of these safety standards. But most importantly, the following job roles must strictly know about the safety standards:

- Professionals indulged in the manufacturing of the Batteries

- People working on the Vehicle Electrification

- Testing Professionals

- Research and Development Team

- Service Technicians

- Interns (if any)

What are the Standard Operating Principles(SOP) for safely disconnecting the High Voltage Circuitry?

To ensure the safe disconnection of the High voltage battery pack following steps must be followed:

Step 1. The vehicle should be in idle condition.

Step 2. A Barrier of about 1 m away from the vehicle should be ensured for the safety of the other people.

Step 3. Place a High Voltage or Danger Sign near the vehicle.

Step 4. Remove any metal wearables from the body and wear insulated gloves and boots.

Step 5. Remove the terminals of the 12V battery of the vehicle.

Step 6. Now Unlock the service plug and then disconnect it from the main High Voltage battery pack.

Step 7. Wait for a while and ensure that the vehicle is not connected to the power source.

Step 8. After ensuring the 0V in the vehicle circuitry, the service work can be done.

Important Link: Electric Vehicle News | Electric Vehicle Blog

Safety Norms for working on High-Voltage Electric Vehicles Conclusion

Since the world is on the verge of huge electrification in every field due to environmental concerns, so EVs are going to be the future. Electrification of the public transport to the private vehicle also draws attention to the fact that we should maintain the safety standards for the proper functioning of the vehicle and the safety of the workers working on them. Scientists around the globe have been working to make the production, use, and maintenance of EVs safer.